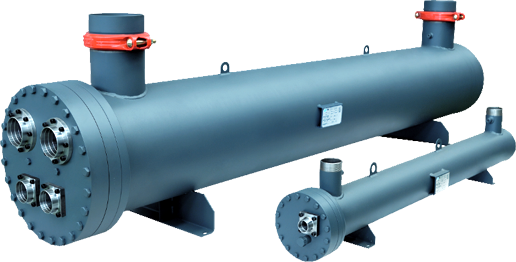

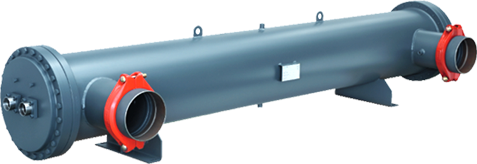

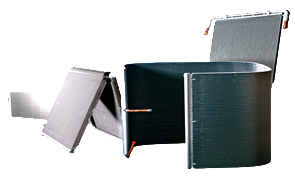

The S&T condenser series CF is of high

performances with all kind of the most common refrigerants (HFC, HCFC, HFO).

The special pattern of the exchanger pipe, designed and machined by WTK, can

be manufactured in a wide range of lengths so to meet all the various

performance and foot-prints requirements.

Some of the model are:

- CF 60 C 4 P

- CF 80 C 4 P

- CF 105 C 4 P

- CF 135 C 4 P